Sharpening stones

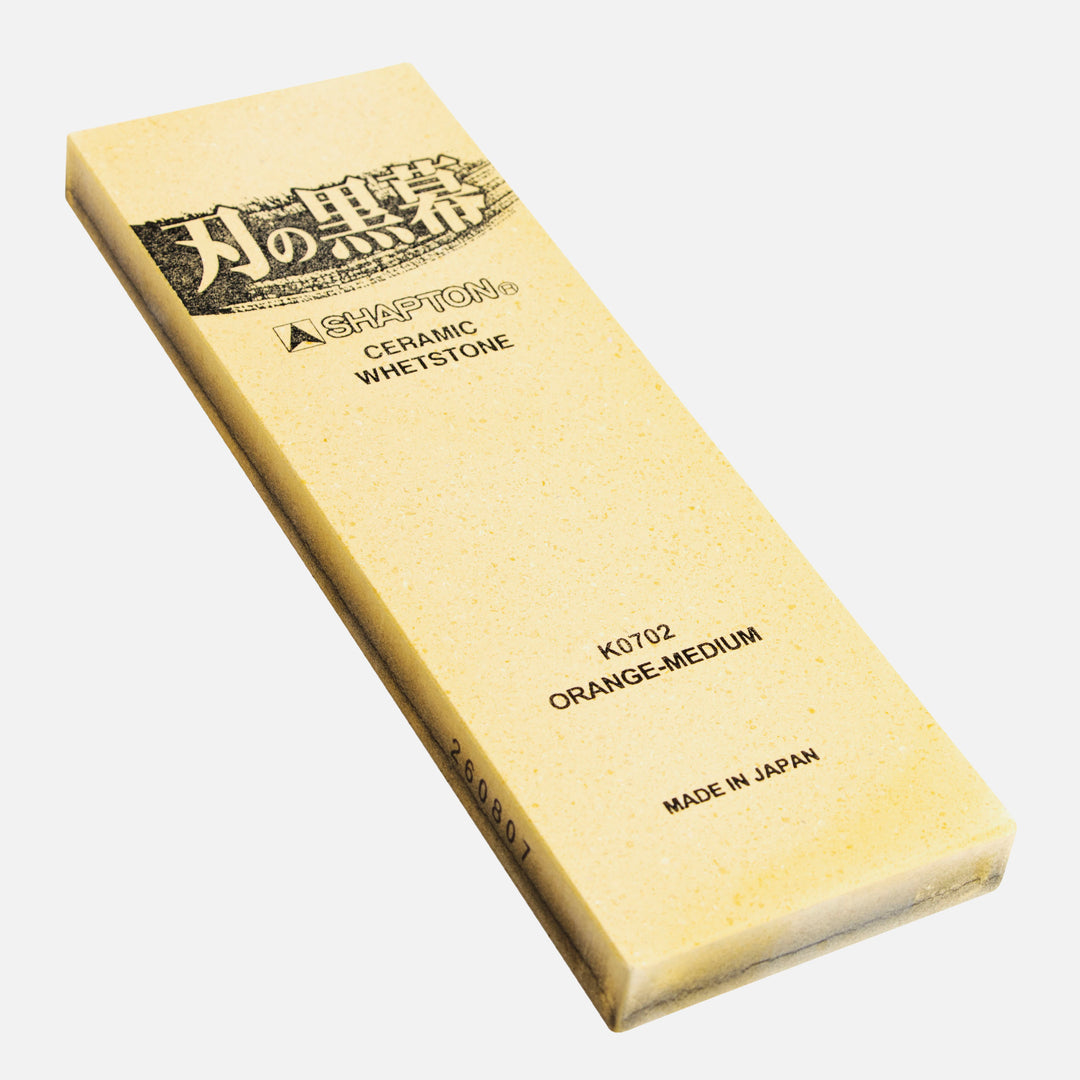

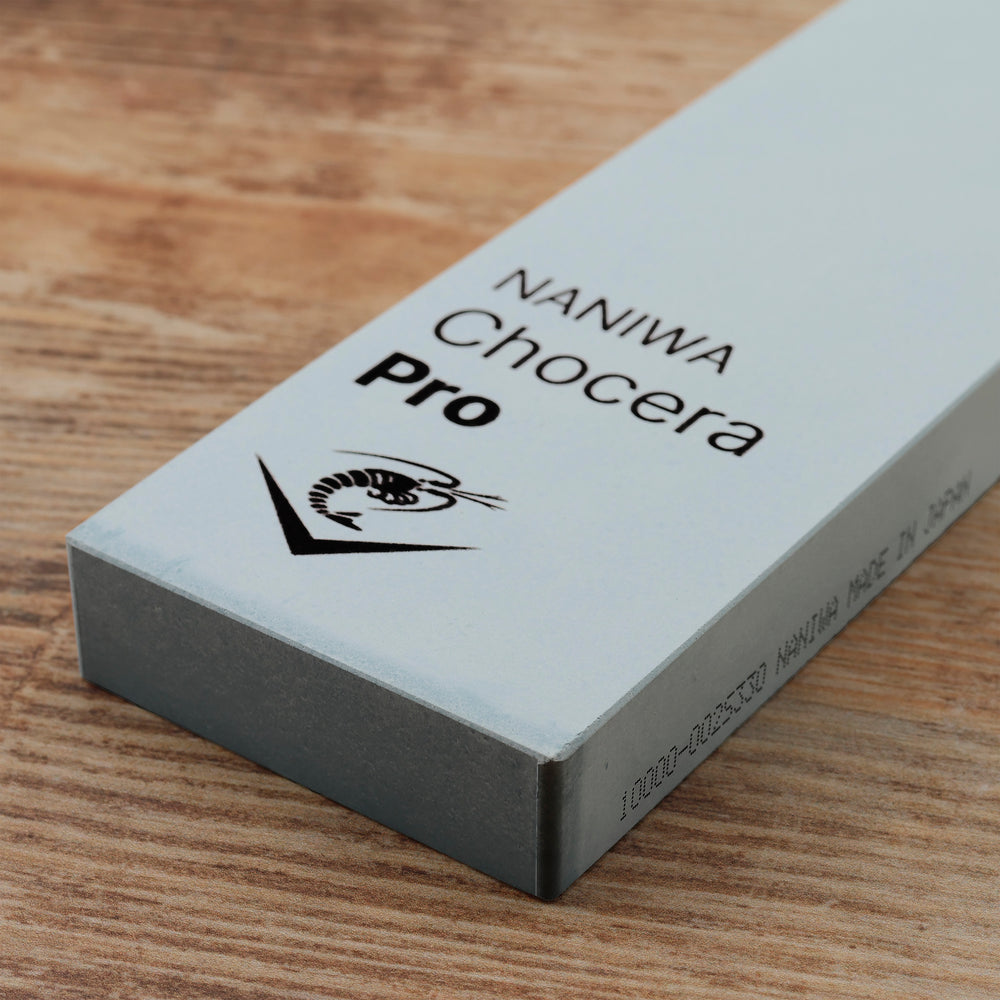

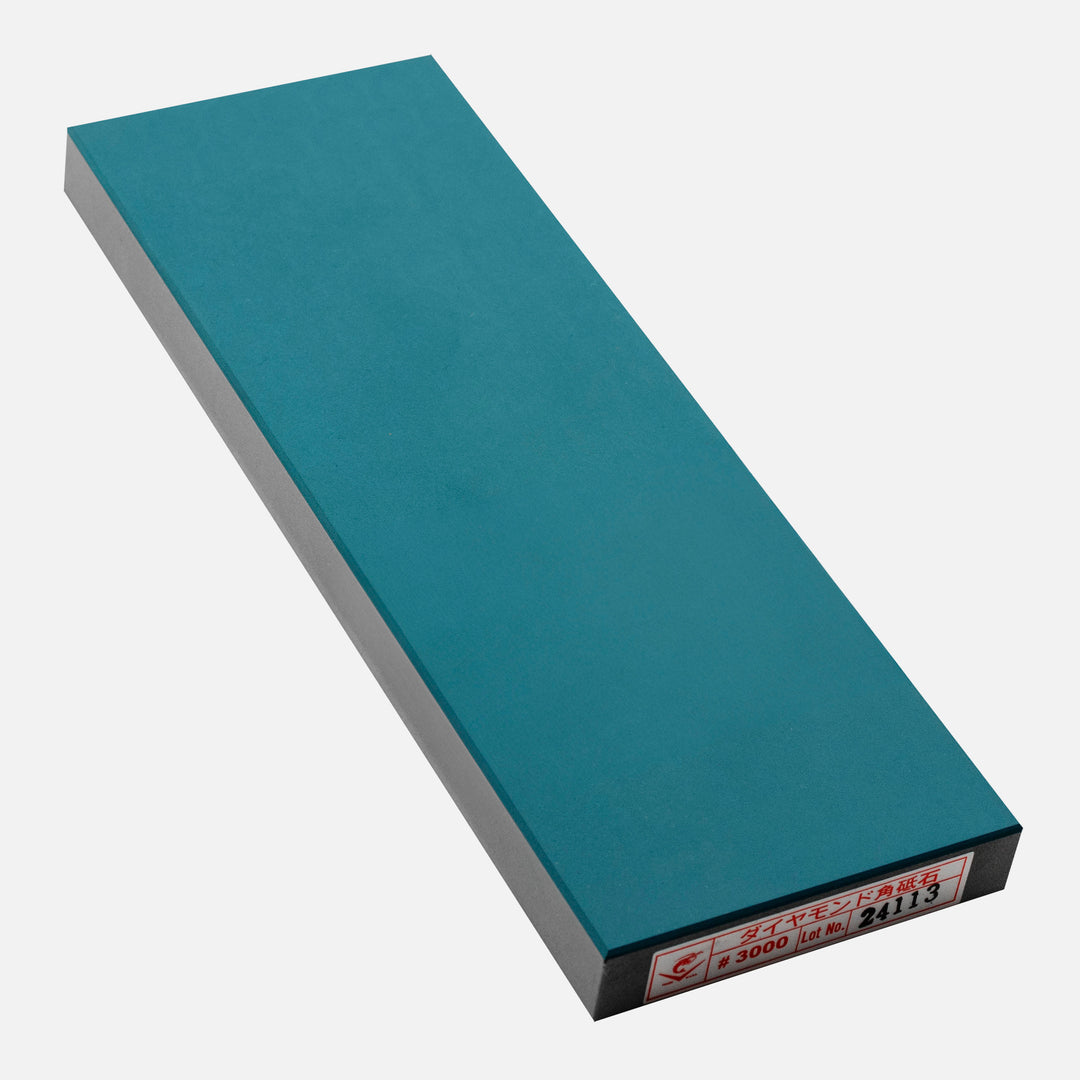

When choosing sharpening stones, there are a few considerations that will determine which of the available models or kits is best for you. First, gradation. The lower it is, the larger the grains of the abrasive will be and the faster it will pick up the steel. Stones with a gradation of 100-400 will be used when it is necessary to lead a completely new edge or when the angle is changed. 500-1000 are gradations that allow you to achieve a decent working sharpness. You can also use stones with a gradation of 3,000 to even 8,000-12,000, or even total unique ones, such as gradation 30,000, but not every alloy will need such a finish, and in some cases it may even reduce the aggression of the cut.

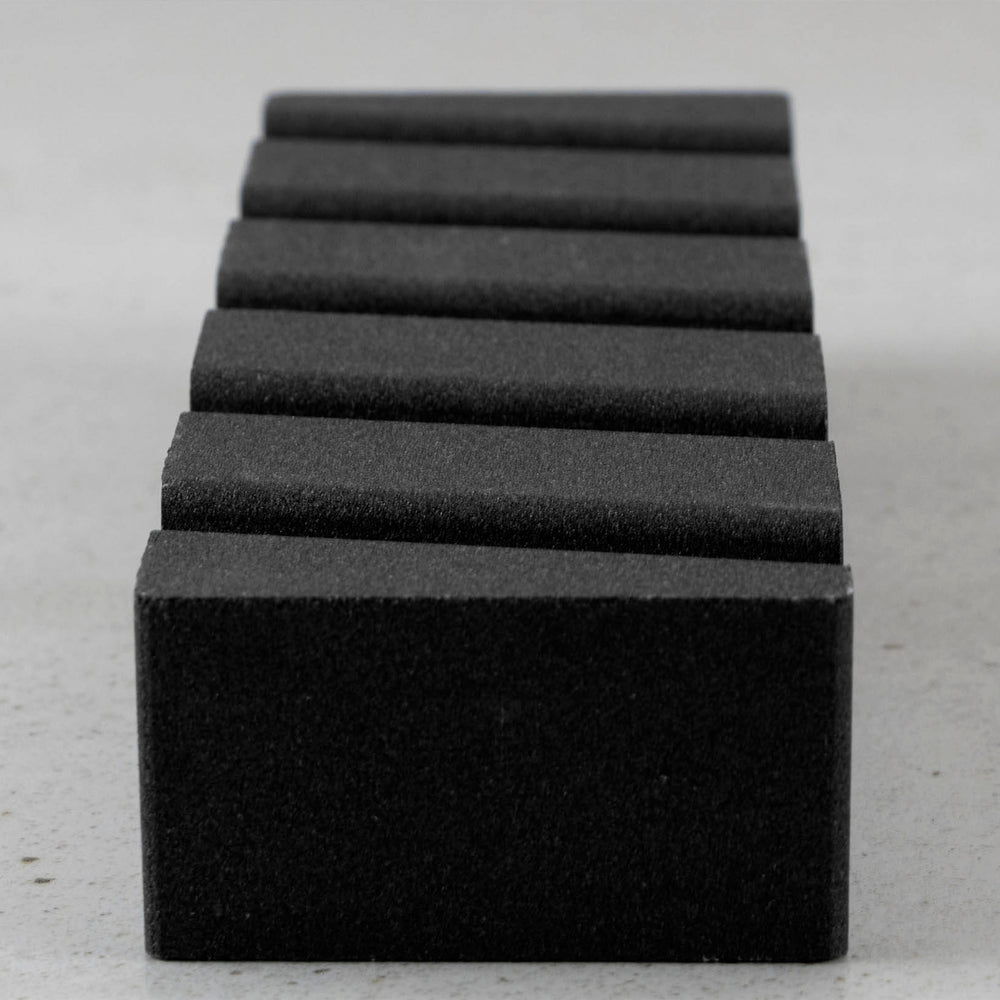

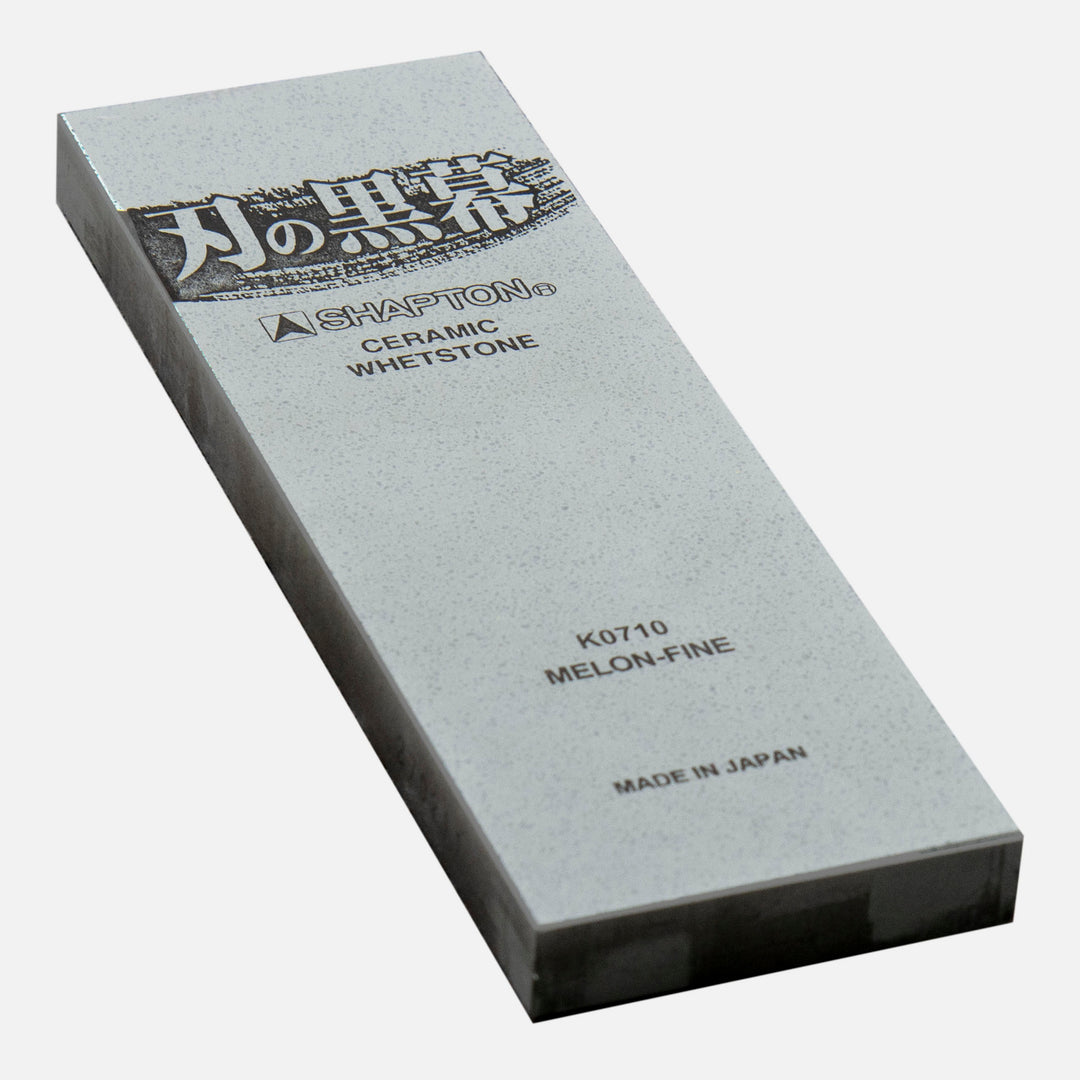

The stones can be either natural or synthetic. Stones cut from natural deposits will be characterized by greater weight and price, which is dictated by the remaining reserves in the deposit, in the case of already exhausted deposits of raw material, some sharpeners gain the status of a collector's product rather than a utility product. Natural stones also require preparation for sharpening - it is best to put them in a tank with water for several minutes, which will allow them to soak up. There are also special "bridges" that allow you to sharpen the knife under a stream of running water, for example over a kitchen sink. It is enough to wet the surface of the synthetic stone to make it ready for work.

Another category of sharpeners are metal diamond plates - synthetic diamonds are characterized by the greatest aggression in terms of collecting material from the blade, thanks to which the sharpening process will take less time, but if you do not have the skill, you can quickly deprive the knife of too much steel. Diamond stones also do not require preparation - they are sharpened dry or with the use of a special oil. With proper use (when using diamond plates, you should not use high pressure - it is best to sharpen using the weight of the knife itself), diamond stones have the longest service life, which additionally increases the profitability of such a purchase.

Depending on the condition of the knife edge, select the first stone with the lowest gradation. Then, to the selected angle, pull the knife over the whetstone several times to one side and repeat on the other side the same number of times, systematically reducing the number of repetitions.