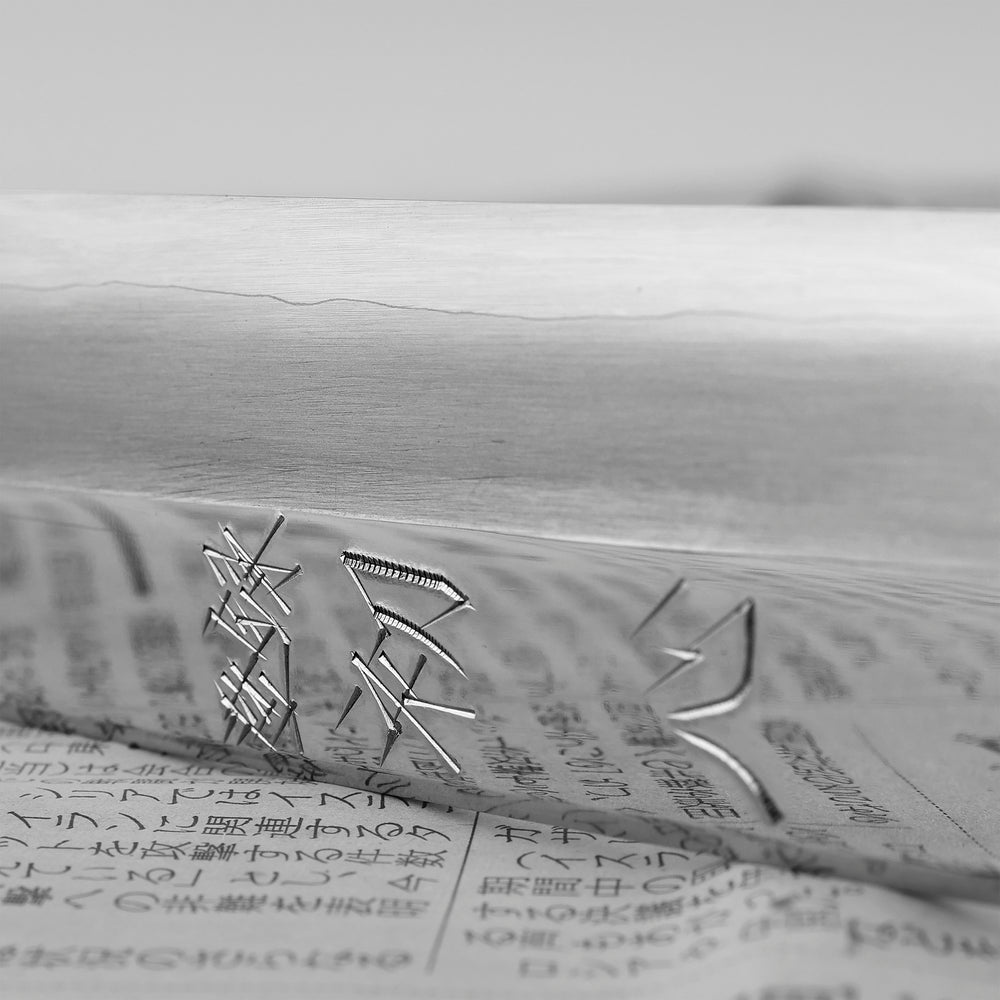

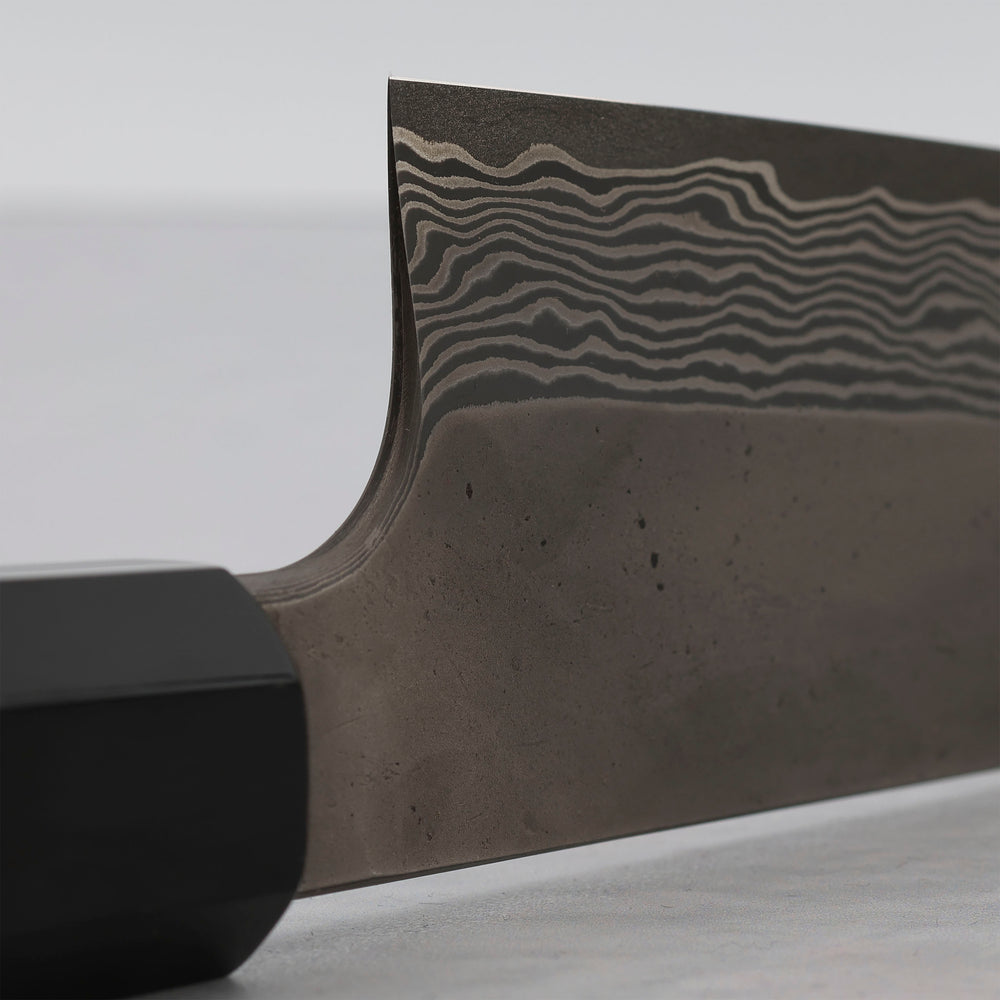

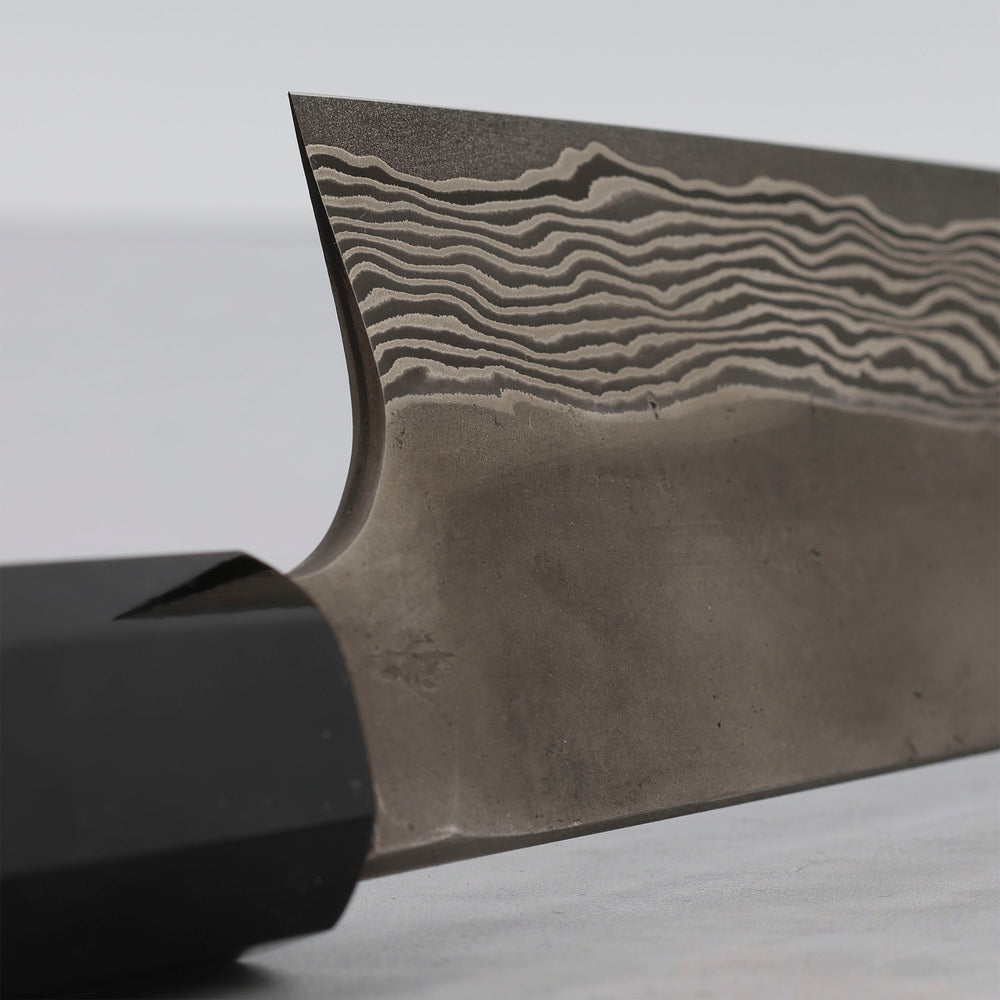

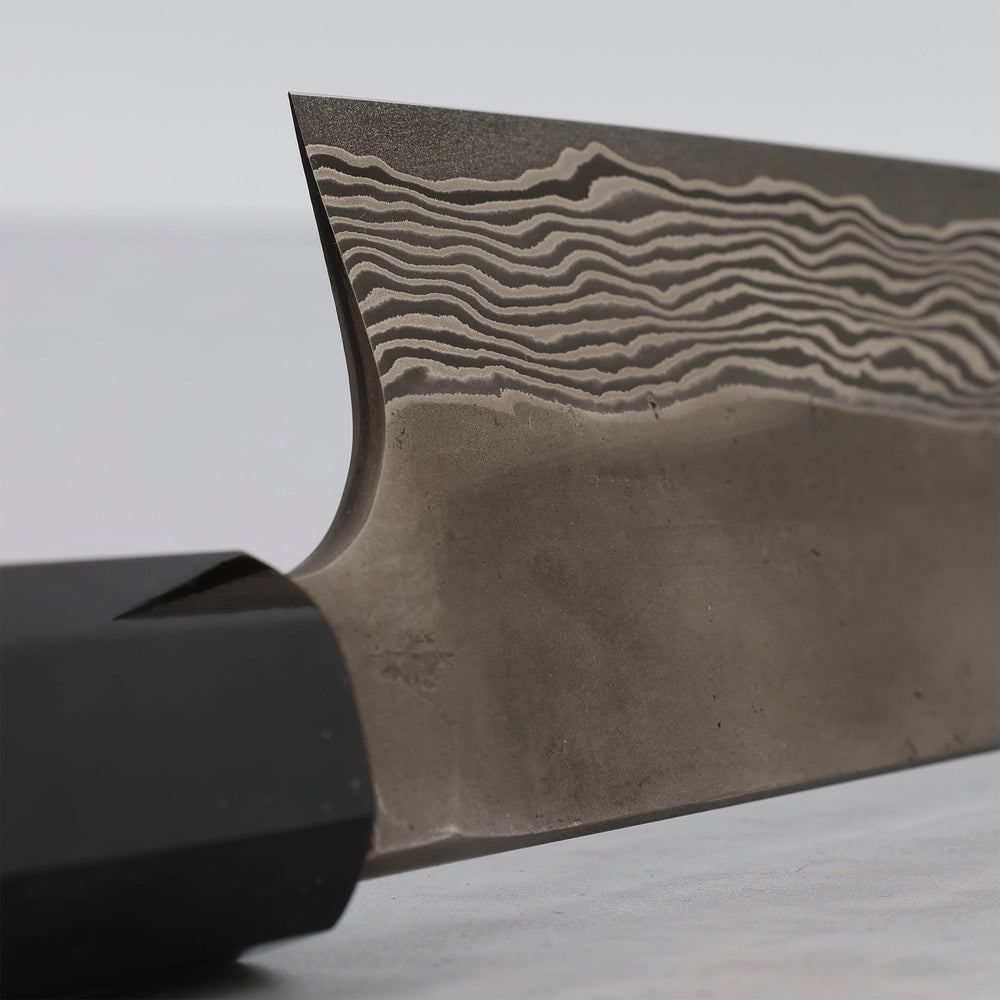

Steel cast by Hitachi Steelworks. It is a unique stainless steel, designed for cutting tools such as knives and shears. It is steel often used in the production of Japanese traditional-style knives. The characteristics of Gingami #3 include:

- High Corrosion Resistance: Due to its high chromium content this steel has excellent corrosion resistance, because of this knives made out of Gingami are highly stain and rust-resistant.

- Hardness: Despite its uncomplicated chemical composition (except for chromium and carbon, it has practically no "functional elements") has an extraordinary hardness, reaching 61 HRC.

- Edge Retention: Thanks to the incredible hardness, knives made of this steel also achieve amazing edge retention. This steel is known for its ability to hold a sharp edge for a long time, making it a good choice for cutting tools that will be used frequently.

- Toughness: While Gingami #3 steel is known for its ability to hold a sharp edge, it is also relatively tough and resistant to chipping or breaking.

- Ease Of Sharpening: Gingami no 3 steel is relatively easy to sharpen, making it a good choice for those who want to maintain their cutting tools at home.

The uniqueness of this steel lies in the fact that hardness and sharpness are comparable to carbon steel. This effect is achieved through a fine-grained microstructure and high carbon content. But these are not the only advantages, Gingami stays sharp for a long time, and when dull, it is easy to sharpen (easier than most stainless steels). In addition, it is characterized by extraordinary cutting aggression. This steel will definitely work for people who do not want to spend time on blade maintenance, but at the same time expect above-average performance from their tools.

Composition:

- Carbon: 0.95-1.10%

- Chromium: 13.00-14.50%

- Manganese: 0.60-1.00%

- Silicon: 0.35%

- Phosphorus: 0.03%

- Sulfur: 0.02%