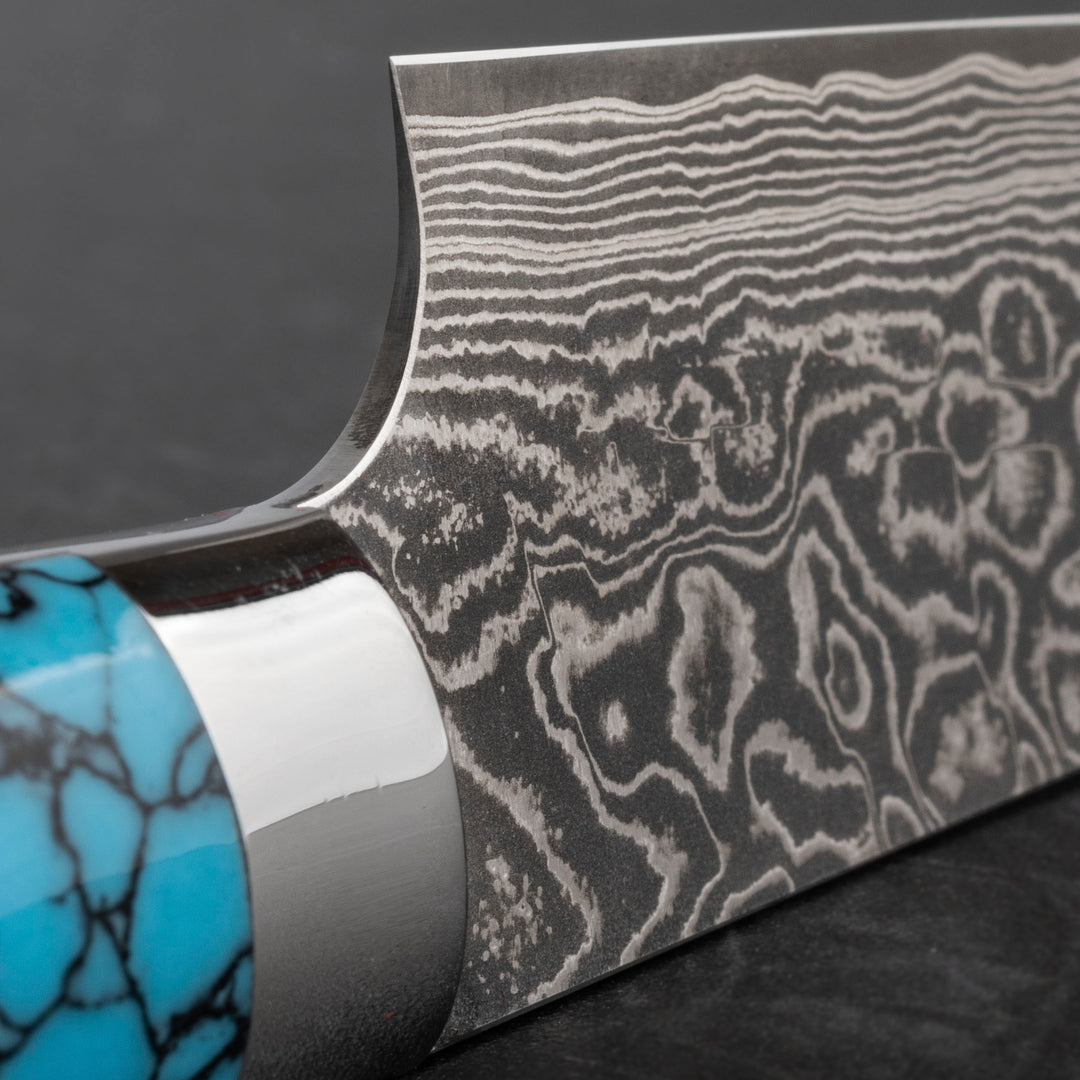

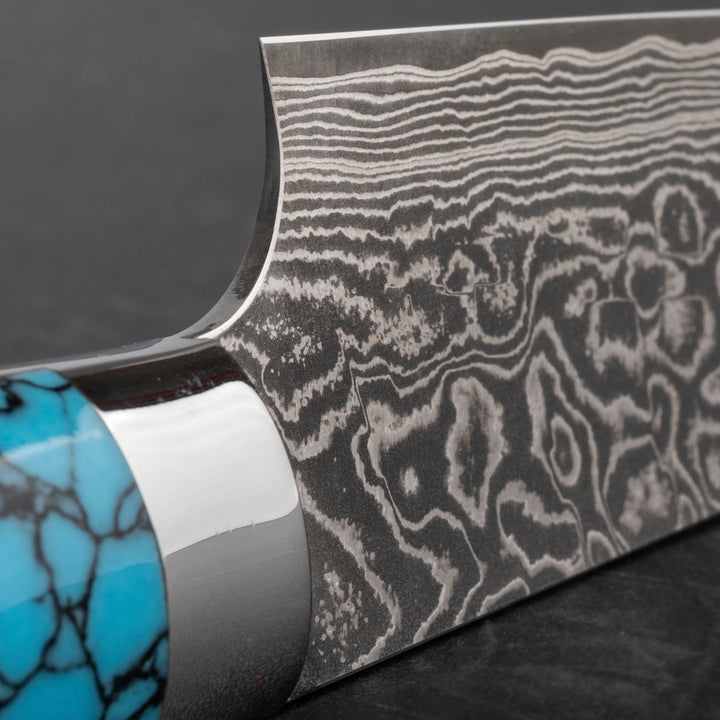

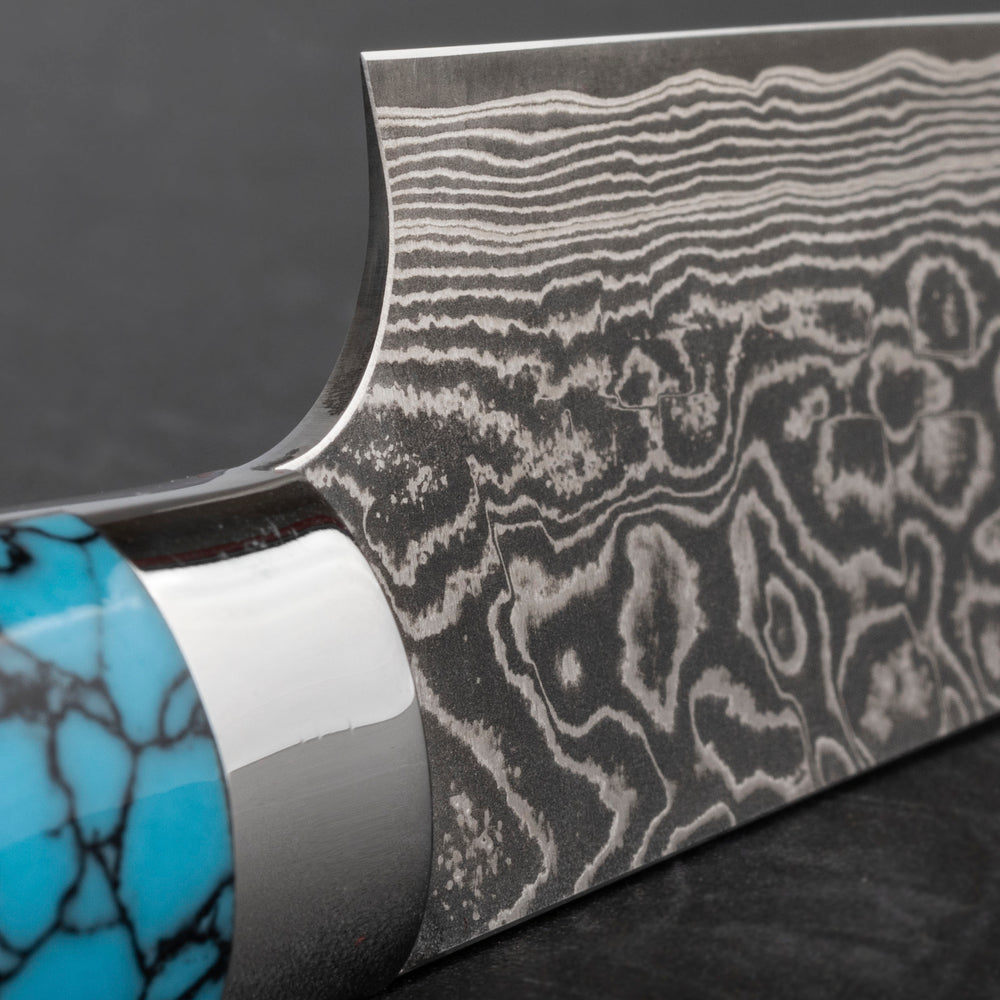

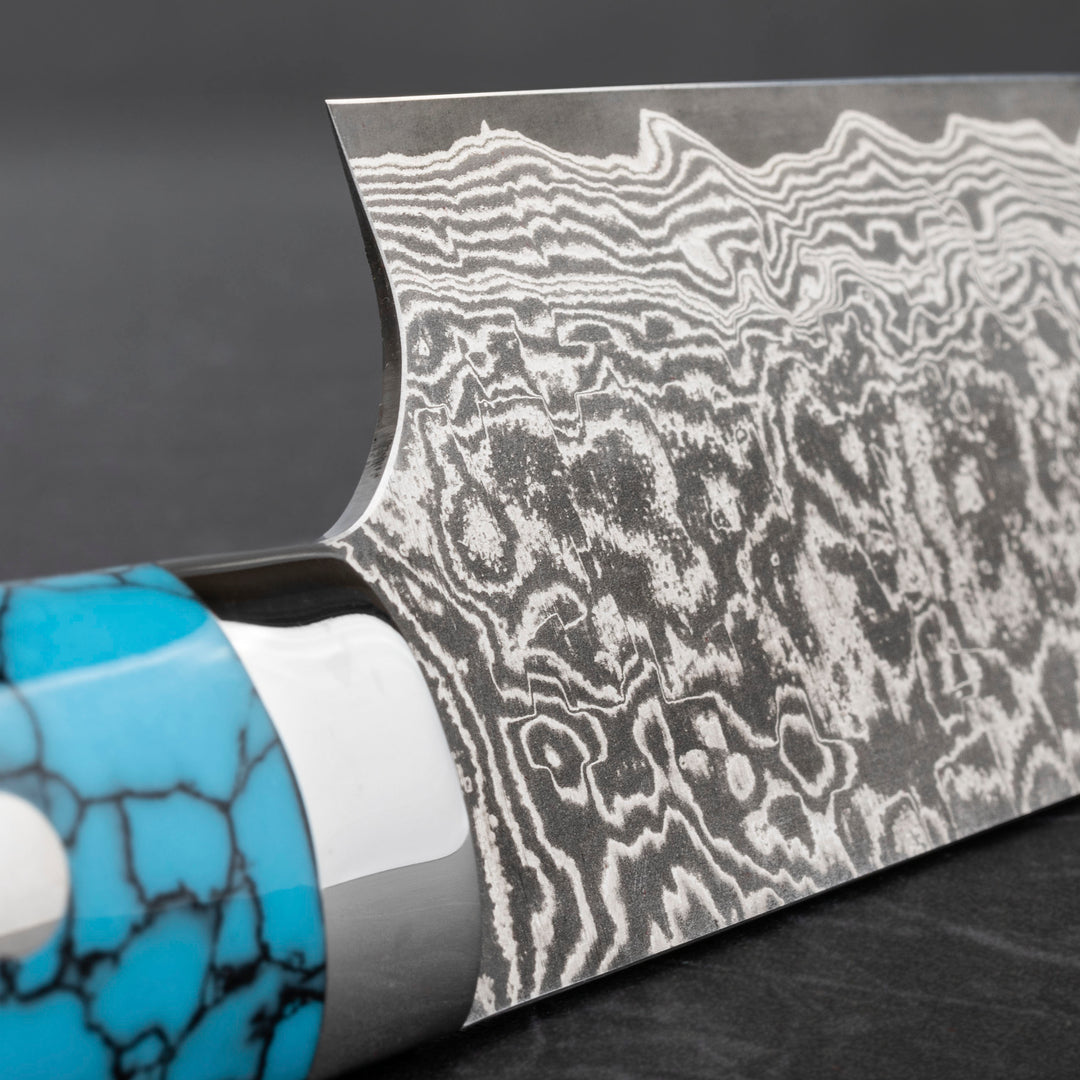

Blade Type: Gyuto

Steel Type: SG2

Mainteance: Powder steel

Takeshi Saji

You may also like

About Japan-knives

Our story (like many others) began with big plans and dreams. We are a group of people with a great passion for Japan, their culture and the knives they create. We wanted to share our passion with you. Each of us specializes in a different field and together we try to create a Japanese knife shop for the 21st century. We do not focus only on sales, the most important thing for us is customer satisfaction, getting to know their impressions of use and the ability to transfer our knowledge to the largest possible audience. To this day, we remember the shock and disbelief after cutting an orange with the first real Japanese kitchen knife we imported. Without thinking and using force. It was enough to take it in two fingers and move it gently - it was "love" from the first cut. Now we know that that impression was just "foreplay" and we learned the real sharpness a few years later.

Tom & Bart Japan Knives Team

Importer Information & Responsible Entity:

- Name: Japan Knives Eliza Szymanska

- Adress: Dereniowa 12, 05-110 Jabłonna

- Email: gpsr@japan-knives.com

- Phone: + 48 788 850 353

Safety information & Manual: